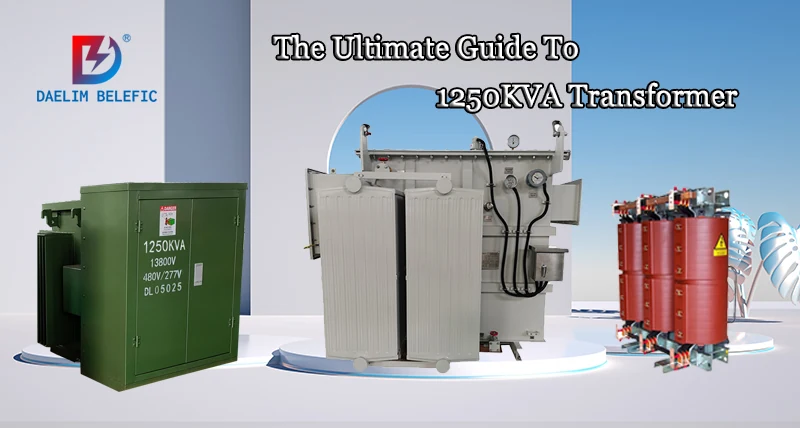

The Ultimate Guide To 1250 kVA Transformer

We all know that transformer is the key equipment in the power supply system, and its main function is to step up or step down to facilitate the rational transmission, distribution, and use of electric energy. 1250kva transformer is one of the most common power transformers. We usually divide it into three different forms, different forms have other functions, and they are usually used in different situations, such as solar energy engineering, renewable energy projects, power distribution systems, public utilities, etc…

DAELIM has been dealing with the design, engineering, and manufacturing of high-electric products and equipment for over 15 years. And we have designed and exported 1250 kva transformer to US and Canada based on UL/CESI certified and CSA labeled. For most customers, DAELIM BELEFIC no wonder is the best choice.

This article will discuss the price, weight, technical parameters, types, and other essential features of 1250kva transformers. And it will give you a comprehensive understanding of 1250kva transformers.

Small-substastion Transformer

Single Phase Pole Mounted Transformer

Oil Immersed Power Transformer

Table of Content

How to choose a Transformer Capacity?

Transformer capacity depends on the choice of calculated load. Determining the load rate of the transformer is the first thing to do when determining the transformer capacity. We all know that when the no-load loss is equal to the load ratio multiplied by the square of the load loss, the transformer has the highest efficiency. And next, let’s discuss how to determine the capacity of the transformer.

In order to improve the operating efficiency and reduce the primary investment, appropriately increasing the load rate of the transformer to reduce the number or capacity of the transformer is the only way to choose when selecting the capacity of the transformer.

Determination of Transformer Capacity:

(1) the factor of impulse current is single motor, arc welding or branch line of electric welding transformer, and the peak current is Ijf=KIN (A)

In the formula,

IN──Rated current of the high voltage side of the motor, arc welding machine, or welding transformer.

K──starting current multiple, that is, the ratio of starting current to rated current.

(2) For power distribution lines connected to multiple motors, only the peak current when one motor starts is considered:

Ijf=(KIN)max+Ifs(A)

In the formula (KIN)max──the starting current of a motor with the largest starting current when starting.

Ifs ─ ─ excluding the calculated current of the starter motor on the distribution line.

For a self-starting motor unit, its peak current is the sum of the currents of all motors involved in starting.

1250 kVA Transformer Type

1250kVA transformer can be divided into 3 different types: Pad mounted transformer, substation type transformer, and dry type transformer. In Daelim, we can make different types according to the different needs of our customers.

Pad Mounted Transformer

The pad-mounted transformer is a commonly used design scheme for 1250kVA distribution transformers. The pad-mounted transformer has the advantages of convenient installation and maintenance. In the Canadian market, the pad-mounted transformer shall be designed based on the CSA C227.4 standard; for the American market and other American countries, the pad-mounted transformer must follow the ANSI/IEEE C57.12.34 standard.

In Daelim, 1250kVA Pad Mounted Transformer can be divided into 2 different designs: Loop feed or Radial feed; Dead front or Live front. Whatever Loop feed or Radial feed, they all specifically designed for servicing such underground distribution loads as shopping centers, schools, institutions and industrial plants. They all use aluminum or copper winding and is optimized to maximize efficiency and footprint. They all have the advantages of high voltage, no drifting of neutral point, low loss, small size, cost-effectiveness, safety and environmental protection, and beautiful appearance. Our Loop feed and Radial feed pad mounted transformer are designed and tested in accordance with industry standards including CSA, ANSI C.57, DOE and IEEE as applicable.

learn more: 1000 kVA Pad Mounted Transformer

Substation transformer

For the substation transformer, 1250kVA is also a common rated capacity. For Daelim, the substation transformer adopts the analysis software of Toshiba in Japan and the unique calculation and program verification of our company to optimize and verify the iron core, coil, device body, wiring, oil tank, and other components of the transformer in order to ensure its performance. The substation transformer produced by Daelim has the characteristics of small size, lightweight, low loss, and environmental protection, which are all due to its superior process design, careful material selection, and efficient manufacturing. These special properties make it highly praised by the majority of users and relevant experts.

Read more: 1000kVA Mini Substation Transformer

Cast resin dry-type transformer

For a cast resin dry-type transformer of 1250kva, the voltage of such a large capacity is usually 35kV. This type of transformer is in accordance with industry standards including IEC726, GB6450, GB/T 10228-1997, and has low loss, small size, low noise, moistureproof characteristics, and so on.

How much is the 1250 kVA transformer?

We know that different types of transformers which prices are not the same by explaining the three types of transformer. There are many factors that affect the price of transformers, such as capacity, type, material, primary voltage, secondary voltage, and so on. If you have the same capacity of the transformer, what are the factors that affect the price?

First, transformer coil material. Transformer coils are usually made of copper and aluminum wires. The price of copper wire is higher than that of aluminum wire, so the price of copper wire transformer is about 30% higher than that of aluminum wire transformer.

Second, transformer core material. The iron core is the main body of the magnetic circuit of the transformer. The iron core is divided into the iron core column and the iron nodule. The winding is set on the iron core column. In the production process, workers will stack silicon steel sheets with a silicon content of about 5% and a thickness of 0.35mm or 0.5mm on the iron core, mainly in order to improve the magnetic conductivity of the iron core. Both sides are coated with insulating paint or oxidized. For the silicon steel sheet in the Chinese market, the smaller the grade, the higher the price, the smaller the turbine loss, and the lower the iron loss, so the transformer’s no-load loss performance is better.

Third, Insulating oil and sudden pressure relay. Insulating oil and sudden pressure relay have a great influence on the price of transformer and pad transformers. Different customers will have different requirements for transformer accessories. All in all, the number of accessories customers require is one of the most important factors affecting the price.

And finally, transformer oil. There are mainly two types of it: vegetable oil and mineral oil. Vegetable oil prices are typically more than three times higher than regular mineral oil prices. We all know that transformer oil accounts for nearly 20% of the total weight of transformer, so transformer oil is also one of the essential factors affecting the cost of transformer.

In comparison between cast resin dry-type transformers with the same capacity and oil-type transformers with the same capacity, the price of the former is higher than the latter. Cast resin dry-type transformers can be equipped with a complete temperature detection and protection system. Using an intelligent signal temperature control system, the working temperature of three-phase windings can be detected and displayed automatically, the fan can be started and stopped automatically, and the functions such as alarm and tripping can be set up. Cast resin dry-type transformer is more stable than oil-type transformer in performance, and the volume of dry-type transformer is relatively small so that it can be used in many places. Therefore, its price is higher than that of oil transformers.

Therefore, the 1250kVA transformer price depends not only on its type but also on its own materials and properties.

learn more: 1500 kVA Pad Mounted Transformer

How much does a 1250 kVA transformer weight?

The weight of different types of transformers for 1250kva is also different.

1250kva pad mounted transformer oil capacity about 690 gals, total transformer weight about 5400kg.

1250kva substation transformer oil capacity of about 396 gals, total transformer weight is about 2900kg

The total weight of a 1250kva cast resin dry-type transformer is about 4500kg.

1250 kVA transformer dimensions

Pad mounted transformer dimension

Date | Offered | Unit |

Height | 1980 | mm |

Depth | 1560 | mm |

Width | 2100 | mm |

Substation transformer dimension

Date | Offered | Unit |

Height | 1610 | mm |

Depth | 1890 | mm |

Width | 1160 | mm |

Cast resin dry type transformer dimension

Date | Offered | Unit |

Height | 2080 | mm |

Depth | 2280 | mm |

Width | 1260 | mm |

1250 kva transformer specification

Pad mounted transformer specification

Rated Capacity | 1250kVA | Product Type | ZGS-Z-1250/12.47 | 60HZ | |

3Voltage Combination | HV(V) | 12470Y/7200 |

BIL | HV(kV) | 95 |

LV(V) | 2400 DELTA | LV(kV) | 60 | ||

Substation transformer specification

Rated Capacity | 1250kVA | Product Type | SL-1250/4.16 | 60HZ | |

Voltage Combination | HV(kV) | 4.16 |

Loss | No-load loss | 1380W |

LV(kV) | 0.4 | On-load loss | 13900W | ||

Cast resin dry type transformer specification

Rated Capacity | 1250 | Product Type |

SCB-1250/35 |

60HZ | |

Voltage Combination | HV(kV) | 35 |

Loss | No-load loss | 3150W |

LV(kV) | 6 | On-load loss | 13400W | ||

Read more: Transformers Selection and Buying Guide

1250 kva cast resin transformer

In the previous part, we discussed the price of cast resin transformer which is giving us a preliminary understanding of it. Let’s discuss the characteristics of cast resin dry-type transformers.

Cast Resin transformer is a widely used electrical equipment in the transmission and distribution system of our country, which plays an important role in the power system. Cast Resin Dry-type transformer has the following characteristics:

(1) safe, non-flammable and fireproof, with no pollution, and can be installed directly in the load center.

(2) maintenance-free, simple installation, and low comprehensive operation cost;

(3) good moisture performance, can operate normally at 100% humidity, and can be put into operation without pre-drying;

(4) small volume, light weight;

(5) high reliability.

Among them, compared with other dry-type transformers, cast resin dry-type transformers have great advantages in overload capacity, insulation level, and short-circuit resistance.

How many amps can a 1250kVA transformer supply?

1250 is the transformer’s capacity which means the apparent power in KVA. When calculating the current, the formula is: current = 1250 / (1.732 * U), and the effective value of the total current is calculated. Rated capacity is rated apparent power or apparent capacity, both of which are the same, but they are called differently.

The rated current on the primary side of 10kv is S = √3*u*I, I= 125 000 / (10 000*1.732) = 72a. If the voltage on the secondary side is 400V, then I = 1.25 million / (400 * 1.732) = 1804a. The nature of I factory is different, the power factor of electricity consumption is also different.

Therefore, 1250kva transformer allows 1804A current to work for a long time, and the maximum continuous current is so large, but it is allowed to overload for a short time, and the overload is related to the overload time. The shorter the time, the greater the allowable excess.

You may enjoy: The Ultimate Guide To Transformer Designs

Why Choose DAELIM?

1. 6-8 weeks production time for pad-mounted transformer and small substation transformer

- Experience in supplying multiple projects in the American Countries such as USA and Canada

3. Qualified with CSA certificate, SGS test report, UL/cUL certificate, etc

- We already cooperated with some NA re-manufacturer transformer suppliers.

If you have any inquiries or projects feel free to send them to DAELIM.