What is Distribution transformer?

A distribution transformer is a pivotal element in the electrical distribution system, serving the ultimate purpose of stepping down high voltage to a usable level for end users. These transformers are crucial in ensuring efficient power delivery and are characterized by their reliability and adaptability in various environments.

This overview encapsulates the essence of the distribution transformer, illuminating its indispensable role in the broader tapestry of electrical infrastructure.

Key Takeaways

Definition: A distribution transformer is essential for stepping down high voltage to usable levels for end users in electrical distribution systems.

Types: Common types include pole-mounted, pad-mounted, and substation transformers, each tailored for specific applications.

Characteristics: Key features encompass voltage ratings, insulation materials, and cooling methods, affecting efficiency and reliability.

Functions: They reduce voltage for safe use, ensuring voltage stability and minimizing energy losses in the distribution network.

History: The development of distribution transformers has evolved alongside electrical systems, enhancing efficiency and adaptability.

Influencing Factors: Performance is impacted by load variations, environmental conditions, and maintenance practices, emphasizing the importance of informed decision-making in selection and procurement.

Skid Mounted Transformer(Small-substastion Transformer)

Single Phase Pole Mounted Transformer

Oil Immersed Power Transformer

Table of Content

Types of Distribution Transformers

Distribution transformers are classified into several categories, including pole-mounted, pad-mounted, and substation transformers. Each type serves specific applications, with pole-mounted transformers often found in overhead lines, while pad-mounted transformers are typically located on the ground, hidden from public view. Substation transformers play a vital role in the transformation of electricity within substations.

Characteristics of Distribution Transformers

Key characteristics include voltage ratings, insulation types, and cooling methods. Commonly used insulation materials are oil and dry types, with oil-immersed transformers providing superior cooling and durability. The size and efficiency of a distribution transformer are influenced by its load capacity and operational environment.

Functions of Distribution Transformers

These transformers facilitate the reduction of voltage from transmission lines to levels suitable for residential and commercial use, thus ensuring safety and efficiency. They also help in maintaining voltage stability across the distribution network, crucial for minimizing energy losses.

Get it now: What is a pad-mounted transformer?

History of Distribution Transformers

The history of distribution transformers is intricately woven into the development of electrical power systems. Their journey began in the late 1800s, when the invention of the transformer itself revolutionized electrical distribution. Early transformers were rudimentary, primarily designed for stepping down voltage in small-scale applications.

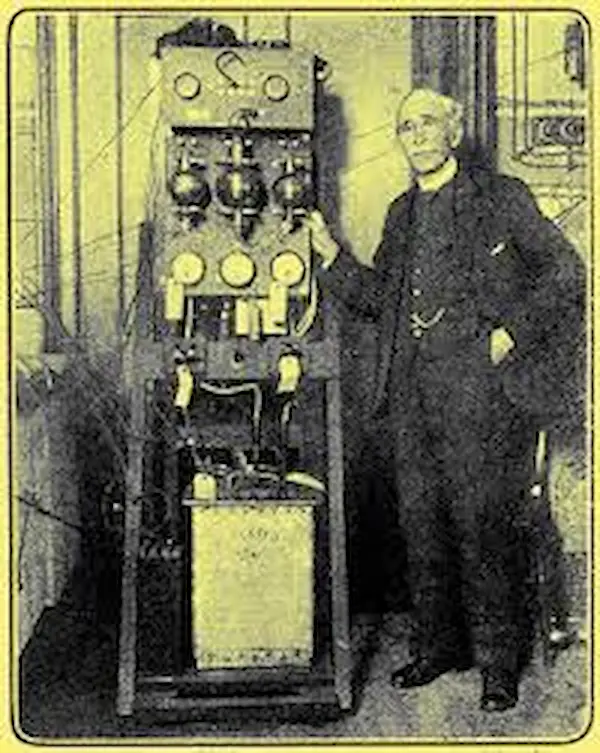

The earliest invention of the transformer is attributed to the renowned American scientist Joseph Henry. In August 1830, while serving as a professor at Albany College in New York, Henry seized the college’s vacation period to conduct groundbreaking experiments on electromagnetic induction. This pivotal experiment demonstrated the principles of magnetic generation of electricity, marking a significant milestone in electrical engineering.

Henry’s experimental apparatus can be considered a prototype of the modern transformer. By utilizing coils of wire and observing how magnetic fields could induce electric currents, he laid the foundational principles that would eventually lead to the development of transformers as we know them today. His work not only contributed to the understanding of electromagnetic induction but also inspired future innovations in electrical power distribution.

By the early 20th century, as cities began to electrify, the demand for reliable power distribution grew significantly. This led to advancements in transformer design, including improved insulation materials and the introduction of oil as a coolant, enhancing efficiency and safety.

The mid-20th century marked a turning point with the widespread adoption of aluminum windings, which offered weight savings and cost reductions. The growing complexity of urban electrical networks necessitated more robust distribution transformers capable of handling increased loads while minimizing losses.

In recent decades, technological advancements have ushered in a new era for distribution transformers. Innovations such as smart grid technologies and renewable energy integration have redefined their role within the power grid. Modern transformers are equipped with monitoring systems that provide real-time data, enhancing reliability and maintenance practices.

Today, distribution transformers are essential to the infrastructure of electrical grids, adapting to ever-increasing demands while maintaining the stability and efficiency that are crucial for contemporary society.

Influencing Factors and Variables of Distribution Transformers

The performance of distribution transformers is intricately linked to various influencing factors and variables that can significantly affect their operation and longevity. Understanding these aspects is crucial for optimizing their functionality in real-world applications.

Load Variations

One of the primary variables impacting distribution transformers is load variation. Fluctuations in demand can lead to overloading, which may cause overheating and reduce the transformer’s lifespan. Proper load management and monitoring are essential to ensure that transformers operate within their rated capacities.

Environmental Conditions

The operating environment plays a vital role in the reliability of distribution transformers. Factors such as temperature, humidity, and exposure to contaminants can affect insulation materials and overall performance. For instance, transformers installed in coastal areas may require additional protection against corrosion, while those in extreme temperatures may need enhanced cooling systems.

Maintenance Practices

Regular maintenance is paramount for sustaining the performance of distribution transformers. Preventative measures, such as routine inspections, cleaning, and testing of insulation resistance, can help identify potential issues before they lead to failure. Effective maintenance schedules extend the operational life of transformers and minimize unexpected downtime.

Sizing and Material Selection

The sizing of a distribution transformer directly impacts its efficiency and performance. An undersized transformer may struggle to meet demand, while an oversized unit can lead to higher losses. Additionally, the choice of materials—such as core construction, winding materials, and insulation—affects the overall efficiency and durability of the transformer.

Load Characteristics

Understanding the load characteristics of connected equipment is crucial. Non-linear loads, such as those from electronic devices, can introduce harmonic distortions that negatively impact transformer performance. Proper analysis of load types and their effects on the distribution network ensures that transformers are appropriately designed to handle such challenges.

External Factors

External influences, such as regulatory standards and advancements in technology, also shape the operation of distribution transformers. Compliance with industry regulations ensures safety and performance, while technological advancements can lead to more efficient designs and materials, ultimately enhancing transformer reliability.

Get it now: What is a Skid Mounted Transformer?

Distribution Transformer Use

Distribution transformers play a fundamental role in the electrical distribution network, ensuring the efficient delivery of power to end users. Their use extends across various sectors, highlighting their versatility and importance.

Residential Use

In residential areas, distribution transformers step down high voltage from transmission lines to safe levels for home use, typically between 120V and 240V. This transformation is essential for powering household appliances, lighting, and heating systems, allowing for the reliable use of electricity in daily life.

Commercial Use

In commercial settings, distribution transformers serve similar functions, but their capacity often scales up to meet higher energy demands. These transformers support lighting, heating, and various equipment in offices, retail stores, and manufacturing facilities. Their ability to handle load fluctuations is vital for maintaining operational efficiency.

Industrial Use

Industries utilize distribution transformers to provide power to heavy machinery and production lines. These transformers are engineered to withstand significant electrical loads and often incorporate advanced cooling systems to prevent overheating. In this context, distribution transformers contribute to the overall productivity and reliability of industrial operations.

Renewable Energy Integration

With the rise of renewable energy sources, distribution transformers are increasingly used to facilitate the integration of solar panels and wind turbines into the electrical grid. They manage the variable output from these sources, stepping down the voltage for safe distribution while maintaining grid stability.

Emergency Services and Backup Power

Distribution transformers are crucial for emergency services, providing uninterrupted power to hospitals, fire stations, and emergency response centers. Their reliability ensures that essential services remain operational during power outages, highlighting their importance in community safety.

Get it now: how to ground a pad mount transformer?