7+FAQ About Copper Transformers

Nowadays, the transformer is a static electrical device that is used to change an alternating voltage (current) of a certain value into another voltage (current) with the same frequency or several different values. The copper transformer is a very common type in the entire transformer market and more and more people choose it because of its better conductivity.

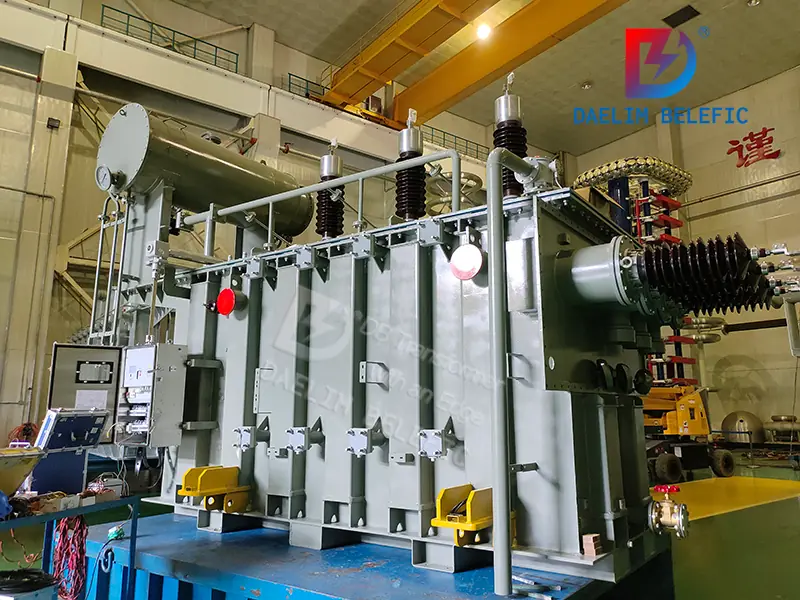

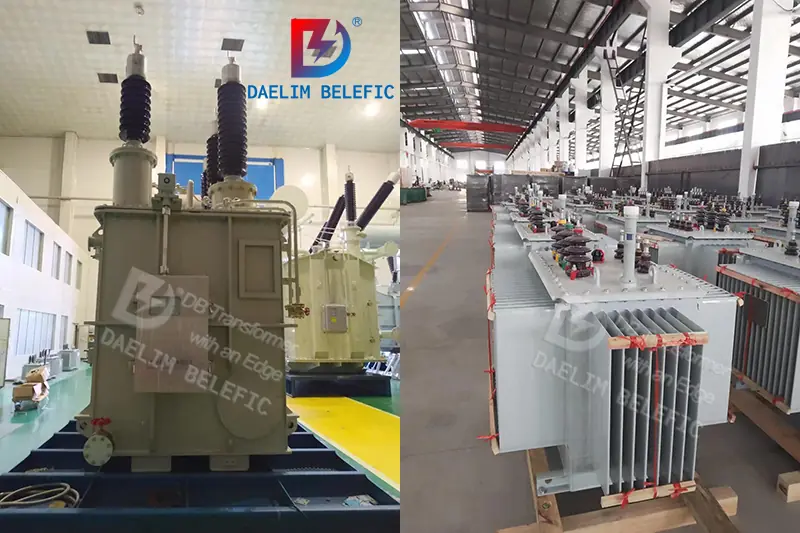

Daelim has been dealing with the design, engineering, and manufacturing of high-quality copper transformers for over 15 years and exporting to U.S. and Canada based on CSA, ANSI/IEEE standards. The copper pad mounted transformer is one of the most common types of copper transformer produced by Daelim. Next, let’s take a more detailed look at copper transformers.

Small-substastion Transformer

Single Phase Pole Mounted Transformer

Table of Content

What is copper transformer?

As we all know, the transformer is an essential power facility in our life today and it is widely used in various fields. For example, transformers can be used in place of switches and interrupt circuits to ensure the user has full control over the current flow through the circuit. This means that the transformer can be used to initiate or terminate the operation of any device or gadget. Furthermore, in addition to controlling operations, transformers also provide the necessary safety for electrical circuits, thereby increasing the lifespan of the product and avoiding premature rupture or failure of the device.

Transformers are classified in different ways. According to the voltage level, classification can be divided into Step Down, Step Up, and Isolation Transformer, it also can be divided into Iron Core Transformer, Ferrite Core Transformer, Toroidal Core Transformer, and Air Core transformer based on Core material.

There is also a common type of transformer we call it cooper transformer, which is used cooper as the winding material. It is the logical choice for most Medium voltage Transformer manufacturers. It not only reduces the volume of the transformer to a certain extent but also facilitates transportation. Because it is harder, stronger than aluminum, and has better connectivity, the copper transformer has become one of the most popular transformer types in the world.

learn more: Basic Guide to Different Transformer Types

What do copper transformers do?

Copper transformer is an essential resource in our life, we use it in different places to facilitate our life. Almost every commercial and industrial building need it. For example, we step up and convert the voltage into high voltage through the power station, then use the transformer to step down the voltage through the high-voltage transmission line, and finally transmit it to the residents or institutions that consume electricity. The density and height of it is high due to the steel casing that usually surrounds them and their service life can generally be as long as ten years.

How much copper in a transformer?

Maybe most of the people don’t know how much copper in a transformer, we take the oil filled copper transformer as an example. In a copper transformer, the copper in it is usually 15% to 20% and the rest is usually mild steel materials and insulating oil.

learn more: The Ultimate Guide To 1250 kVA Transformer

Copper vs aluminum transformer

Usually, transformer manufacturers will choose to use aluminum as the winding material, but some electric experts prefer to use copper as the winding material to meet the special requirements of customers. Next, let’s look at some of the differences between them.

Among the many electrical conductors, copper performs very well. Although copper windings and aluminum windings provide similar functions when the volumes of copper and aluminum are equal, we can find that aluminum’s conductivity is about 62% of copper, making copper a much more effective conductor. Transformer windings need a certain strength and resistance to deformation, and copper can satisfy this well, which is what we usually call reliability.

Aluminum is more flexible than copper making it easier to wind in production processes and there is a very thin layer of oxide on the surface of aluminum, which can prevent air and water from entering the metal, thus resisting corrosion.

The initial costs of aluminum windings are cheaper than copper windings for the production cost of the material itself is relatively low and the price of aluminum has remained stable for a long time. In order to reduce the cost of the magnets, oil tank, and oil used, we chose copper as the winding material as it reduces the size of the transformer. In terms of price, copper is indeed more expensive than aluminum, but it can bring longer-term benefits.

An aluminum-wound coil is larger than an equivalent copper coil, which means it needs approximately 1.8 times the cross-section of copper to carry the same amount of current. When talking about the current carrying capacity, we can find that copper is twice as much as aluminum, which also allows the size of the transformer to be reduced.

For the operating life, under the premise of correct installation, the operating life of copper and aluminum is basically the same but aluminum is more difficult to install which may result in some problems. Copper is usually the best choice for preventing fault current stress and extending overall life.

Read more: Transformers Selection and Buying Guide

How do I know if my transformer is aluminum or copper?

First of all, we can usually find the winding material on the nameplate but if there is no nameplate, one way to determine the material is to scrape some of the enamel off a small section of wire where it connects to a terminal, away from the windings.

Another method that requires more knowledge about the transformer is to check the weight. If the core volume is measured, the weight of the core can be calculated. An estimate of the winding volume will allow you to calculate the density of the windings. The huge weight difference between copper and aluminum, almost a factor of 3, will give you a good idea of the winding material.

Which transformer is better copper or aluminium?

Transformer manufacturers and installers have been discussing the question – Which transformer is better copper or aluminum? for a long time, but there is never a definite answer, both are vying to be the number one contender for the ideal component for transformer windings. Copper and aluminum transformers each have their own advantages.

Although copper windings and aluminum windings serve the same purpose in a transformer copper is more reliable. The reason why we choose copper is also because of its relatively strong conductivity, and the conductivity of aluminum is only 63% of that of copper.

Size is a key factor to select copper. The importance of the size of the winding is shown when there is a problem with the equipment, it is large enough to withstand the load caused by the fault. Size is also at a premium for high-rise facilities.

Because the power equipment related to the transformer usually needs to be guaranteed to be used for a long time and not easy to be damaged, another reason we choose copper is its connectivity, which can make the connection of the equipment stronger and less prone to corrosion. Copper connections remain tight and will not corrode and there are some copper structures with no aluminum version.

In the early days, aluminum transformers were most people’s first choice because people were more cost-conscious at that time, aluminum was plentiful and reasonably priced, cheaper than copper. As a result, it quickly became the metal of choice for high-power transmission power lines. But then they met more technical problems than those who used copper transformers. In terms of service life, let copper windings and aluminum windings work in the same environment for a certain period of time, aluminum is much lower than copper, which also means that aluminum transformers will fail earlier than copper transformers.

Choosing a copper transformer does not mean that the cost must be higher. The cost of the transformer usually includes the cost of the conductors as well as custom magnets and the cost of the tank and oil. Under the same resistance, the cross-sectional area of the aluminum conductor needs to be 1.66 times larger than that of copper in order to achieve the same effect. This results in a larger transformer core and volume, which also results in a larger transformer tank than copper designs. But if we choose copper, the size of the iron core can be reduced, the amount of steel, insulation materials, and oil used can also be reduced, and a smaller radiator can be used for cooling.

But that doesn’t mean we only have copper transformers as an option. All the major manufacturers have, for many years, manufactured transformers utilizing both aluminum and copper winding conductors. The choice of material mainly depends on the technical project specification or client preference. Experienced transformer manufacturers have the proper knowledge and experience of the technical “pros and cons” of any one conductor material and can provide the best technical solution for any given project. Both winding materials provide low-loss, highly reliable transformers with the same technical performance.

You may enjoy: The Ultimate Guide To Transformer Designs

Final Thoughts on copper Transformers

- Copper stands out among many materials and becomes the first choice for many Medium voltage Transformer manufacturers. Its smaller size not only facilitates transportation but also saves the materials needed in other parts.

- The robustness of copper makes it more resistant to stresses imposed by fault currents and less prone to deformation, thus extending transformer life and reducing life cycle maintenance costs.

- The better connectivity of copper not only prolongs the service life of the equipment but also ensures that the entire equipment is in a tight state

Daelim Transformer Manufacturer

Daelim not only provides high-quality copper transformers but also other types of transformers. Daelim’s transformer service center can help you design and produce distribution transformers, pad mount transformers, substation transformers, and single-phase transformers that meet your unique needs.

We have the most professional engineers and a well-equipped factory, which can meet various requirements of customers.

If you have any questions about the copper transformers or any other transformers you need, welcome to send emails to service1@daelim-electric. com. We will give you the best solutions