The Ultimate Guide To Oil Type transformer

As we know, there different type of transformers, in this article, we are going to talk about Daelim oil type transformer. Daelim is by a team of professionals who can offer you the best solutions for your projects that require oil type transformers.

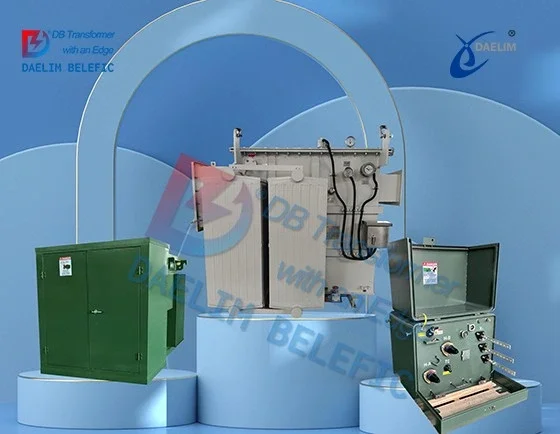

Pad-mounted Transformer

Dry-type Transformer

Oil immersed transformer

Table of Content

WHAT IS OIL TYPE TRANSFORMER?

Oil type transformers are characterized in that their magnetic circuit and windings are completely submerged in oil. This is used as an insulating liquid, it can be silicone, mineral, ester or vegetable and its choice will depend on the needs of the client and the type of installation.

Oil type transformer is a kind of voltage transformation device utilizing the oil cooling method to reduce the transformer temperature.

Oil in transformers is used for insulation, to stop arcing and corona discharge and to dissipate heat from the transformer, i.e. it acts as a coolant.

In addition to its use to preserve the core and windings, since they would be completely submerged in oil. At the same time, it avoids direct contact between oxygen and cellulose, thus avoiding its oxidation.

In addition, because oxygen can not enter the oil tank, thus avoiding the aging of insulation materials, improve the service life of the product, but also improve the social benefits.

Keep on reading VIETNAM CUSTOMERS

TYPES OF OIL TYPE TRANSFORMER

The main oil type transformer that Daelim has are the follow transformers:

– Pad mounted transformer

– Distribution transformer

– Power transformer

– Small substation transformer

PAD MOUNTED TRANSFORMER

In general, Pad mounted transformers are equipment mainly used for the distribution of energy. Our pad mounted transformers are connected to underground utility distribution lines, to reduce the primary voltage to the secondary voltage to be supply to the final customer.

These type of transformers are normally installed outdoor, placed on a pedestal, inside a tank made by mild steel material or stainless steel material, with two doors and a door lock to guarantee their safety.

Daelim Pad mounted transformer are available with electrical grade mineral insulating oil or FR3 fluid. The applied liquids are to improve the efficiency, to low the risk of accidents, and the most important, to collaborate with the environment.

FR3 fluid can improve the fire safety and environmental benefits of the transformer improving at the same time the life of the pad mounted transformer in this case.

Try for free information about the VENEZUELA CUSTOMERS

DISTRIBUTION TRANSFORMER

Distribution transformers are important equipment in the distribution network and power supply and distribution systems of industrial and mining enterprises. One of the main advantages is the compact structure, small size, low noise, and this oil type transformer has an hermetically sealed type and conservator type.

This oil type transformer is applicable in a mine, petrol chemical and other power distribution systems.

Mineral oil is the most used for this type of oil transformers. Among other insulating liquids you can also find vegetable oil.

Read my article on Know More About Tips of single phase transformer

POWER TRANSFORMER

This transformers are the main component in the electrical grid. The oil transformer has a huge capacity, so in that way will save a lot of electrical energy, minimize power loss and this make reduce the costs of the clients at the same time. Also in this case, the oil in the transformer helps to the durability and electrical properties of transformer equipment.

SMALL SUBSTATION TRANSFORMER

Small substation transformer is another kind of oil type transformer. As we mentioned before, the oil helps transformer to extend their life and avoid damages.

WHAT TYPE OF OIL IS USED IN OIL TYPE TRANSFORMERS?

One of the main fluid we use for oil type transformer is FR3 high-fire-point dielectric fluid. This kind of fluid can improve the fire safety and environmental benefits of the transformer and at the same time extend the service life of the equipment.

The important properties of vegetable insulating oil is their higher flash – fire point and biodegradability than conventional mineral oils.

Another of the most used oil is mineral oil. This is a high-grade transformer oil made from moderately refined low-viscosity and low-pour-point naphthenic base oil, and is blended with premium antioxidant compound additives. Featuring with rapid heat transfer, good oxidation stability and excellent electrical performance and is produced from stable resources under strict quality control system.

This mineral oil has good electric insulation performance, high breakdown voltage and low dielectric loss factor, can effectively prevent discharge and power loss in high voltage electric fields, good thermal stability and oxidation stability. Also can prevent the formation of acids and sludges during the using process, and extend the life of electrical equipment. Additionally because of the lower viscosity, this mineral oil provide effective cooling and heat transfer.

DIFFERENCE BETWEEN DRY TYPE TRANSFORMER AND OIL TYPE TRANSFORMER

There are two main types of transformers that we use right now, one is oil type transformer and other is dry type transformer. They have the same function, but there are many differences between them.

The main difference between dry type transformers and oil type transformer is the cooling method, dry type uses air as a cooling medium, and oil type transformers use oil. The cooling medium is important for the overheating which is inevitable when transformers are under load.

Oil type transformers have higher standard energy efficiency, and higher results than dry type.

Another difference between them is the maintenance, oil type transformers require more maintenance procedures than the dry type. Oil type transformers require the oil change more often, to extend transformer life and avoid damage.

In terms of price, oil type transformers are cheaper than dry type.

At the same time, all type of transformers make noise when they are working, but in we have different options and different levels of noise. In this case, if we compare oil type transformer and dry type transformer, the best option for lower noise is oil type transformer, that provide you lower level of noise.

Another big difference is the efficiency, oil type transformers are known to be more efficient than dry type transformers, which are limited in their voltage and their ranting and size.

These are the main differences that exists between oil type transformer and dry type transformer. In Daelim, we can provide the best solution for our customers according to their requirements, letting them choose the best option for their solutions.

Know more about SPAIN CUSTOMER

WHY DO WE USE OIL IN THE TRANSFORMERS?

Oils are key components for the operation of high-voltage transformers in the national electricity system, especially from the point of view of safety, where the maintenance of the liquids of these equipment is essential to avoid possible failures that could endanger the electrical supply.

Oil in transformers has the function of being insulating and cooling. Its working mechanism is to impregnate the paper that surrounds the copper of the coils in the transformer and transport the heat generated at this point to the outside. Additionally, the oil protects the equipment against electrical discharges inside, which can damage the insulation, its parts, or in the worst case, cause a total loss of the transformer, thus resulting in a fire.

Daelim has more than 15 years of experience in transformer industry, and we exported to more than 30 countries around the world. Thanks to this, we have the experience and the advantage to have a professional tech team and production team at the same time. This 15 years of experience gave us the opportunity to be familiar with international standards and follow all the rules for design and production as per customers requirements.

Also, our factory of transformers is located in China, so we have really good raw material supply chain and we can always provide competitive prices to our customers around the world.

Filling oil in transformers is an extremely delicate activity that requires the intervention of qualified experts who follow the appropriate procedures for this operation, in addition to properly trained personnel. But thanks to the points we mentioned before, Daelim has a team of professionals who follow all the rules according to international standards.

We already know that oil type transformers have a big number of advantages. One of the main advantages of this transformer is to help improve transformer safety and increase the benefits that oil brings to transformers.

In addition to the advantages, we must also take into account changing it as part of maintenance. After a while, the oil loses its insulating and cooling properties, therefore it needs to be changed. In this way, we can avoid costly damage and also extend transformers life.

To make sure the quality of tank vacuum oiling, DAELIM have a leak test in the end of welding and assembling works and de-rusting by sandblast when it pass the test.

You may interested in Choose DOE Energy Efficient Single Phase Pad Mounted Transformer

DELIVERY AND STORAGE for the oil filled power transformer

The equipment shall be completely assembled and tested before shipment, disassembled if required for shipment and all parts match-marked to facilitate assembly and erection. The unit shall be suitably braced and packed for shipping to prevent breakage and distortion which in transit. All crates, boxes and cartons shall be clearly marked so that equipment can be readily identified. Shipping invoices shall show the crate, box or carton identification number. The equipment shall be shipped in sections as described in the proposal or as directed by the owner.

All shipments shall be made by motor truck unless prior approval has been granted for other method of shipment.