A Complete Guide to 225 kva transformer

225 kva transformer is generally used in distribution system, in this article we will introduce some tips about distribution transformers.

Pad-mounted Transformer

Dry-type Transformer

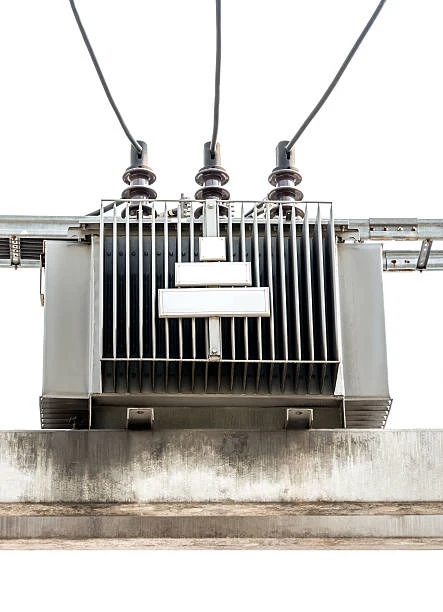

Oil immersed transformer

Click below for quick review of 3 phase transformer

Which cable is used on the low-voltage side of a 225 kva transformer?

Empirical formula; it can be selected according to the copper core cable per kvA1 square millimeter, then 250kvA*1=250mm2, the public (common) can be changed to 4*240mm2 copper core

Power cable, factory and mine special change can choose 3*240mm2+1*120mm2 copper core power cable.

Try for free High voltage transformer – 138kv power transformer

What is the meaning and method of measuring the winding resistance of a 225 kva transformer?

Let’s first look at the consequences of transformer oil leakage:

1. Transformer oil leakage not only seriously affects the appearance, but also causes economic losses because the transformer needs to be shut down to eliminate leakage.

2. Oil leakage will seriously interfere with the operation and maintenance personnel’s monitoring and judgment of the sealing condition in the transformer oil conservator and the correctness of the indication of the oil level gauge.

3. After the oil level is lowered due to leakage, the live connectors and switches may be operated without oil insulation, which may lead to breakdown, short circuit, burnout, and even cause equipment explosion.

4. After the transformer oil leaks, the fully sealed transformer will lose its sealing state, which will easily make the oil-paper insulation suffer from the intrusion of the outside air and moisture, which will reduce the insulation performance, accelerate the aging of the insulation, and affect the safe and reliable operation of the transformer.

How to deal with transformer oil leakage, let’s take a look at the specific treatment measures in combination with the case:

The transformer valve core of a power supply company leaked oil, and most of the valve core valve stem seals failed, resulting in serious oil leakage. Due to the special working environment of the transformer, it was not allowed to stop for a long time, so it could not meet the needs of replacing new parts. The use of Soleil carbon nano-polymer material technology is a more effective way to solve the transformer oil leakage at present.

The operation steps for on-site treatment of transformer oil leakage are as follows:

(1) Clean up the oil stains on the leaking part, and polish around the leaking part to expose the primary metal color;

(2) Clean up, clean, dry, firm and rough after surface treatment;

(3) Reconcile the SD2240 material and seal the leaking parts until there is no leakage;

(4) Reconcile SD7111C material, apply it to SD2240 and metal surface, and completely solve the leakage after the material is cured;

(5) The surface is sprayed with a layer of paint, so that the color is consistent with or similar to the equipment body, and the aesthetics is improved.

Read my article on Know More About The Main Transformer – DAELIM

What is the 225 kva transformer specification?

Below is specification for 225 kva pad mounted transformer, in the specification we can also see 225 kva transformer dimensions.

To know more about 225 kva pole mounted transformer, 225 kva dry type transformer, click below links:

Transformer, Single Phase, Pad Mount,225 kVA 4160GrdY/2400:12470GrdY/7200V | |||

| |||

| |||

| |||

|

|

|

|

ITEM | DATA | UNIT | Offered |

1 | Supplier | …. | Beijing Daelim |

2 | Model | …. | ZGDL11-H-225/2.4-7.2 |

3 | Country of origin | …. | CHINA |

4 | Standard manufacturing and testing | …. | IEEE Std. C57.12.00 IEEE Std. C57.12.90 |

5 | Features |

|

|

5.1 | Type |

| Loop feed pad mount |

5.2 | Installation |

| Outdoor |

5.3 | Altitude above sea level/Ambient temperature | m/℃ | 1000/50 |

5.4 | Altitude |

| ≤1500m |

5.5 | Rated Power | kVA | 225 |

5.6 | HV | V | 4160GrdY/2400 |

5.7 | LV | V | 12470GrdY/7200 |

5.8 | Rated Frequency | Hz | 60 |

5.9 | Cooling System |

| ONAN |

6 | Number of winding |

| 2 |

6.1 | Number of phase |

| 1 |

6.2 | Core/Shell |

| Core type |

6.3 | Refrigerant |

| Mineral oil 45# (PCB FREE) |

6.4 | Working-Temperature | °C | -50°C to +40°C |

6.5 | Cooling Method |

| ONAN |

6.6 | The temperature rise -Top oil | °C | 65 |

6.7 | The temperature rise –Winding | °C | 65 |

6.8 | Hot spot | °C | 80 |

7.1 | Losses |

|

|

7.1.1 | No load losses at rated voltage and rated frequency on principal tap | W | 500 |

7.1.2 | Load loss at rated voltage | W | 2000 |

7.1.3 | Tolerance |

| NLL:±15%,Total loss: ±8% |

7.3 | Core material |

| Grain oriented silicon steel |

7.5 | Winding material |

| Copper |

7.6 | Tap changer |

|

|

7.6.1 | On load or off-circuit |

| off-circuit |

7.6.2 | Position of tapped winding |

| HV |

7.6.3 | Tap Voltages HV | % | ±2×2.5% |

7.6.4 | Highest voltage for the enquipment | kV | 35 |

7.6.5 | Rated current of tap changer | A | 63 |

7.7 | High voltage electrical characteristics of transformers and assembled load break terminals |

|

|

7.7.1 | Insulation class | kV | 5 |

7.7.2 | BIL | kV | 60 |

7.8 | Low voltage |

|

|

7.8.1 | Insulation class | kV | 15 |

7.8.2 | BIL | kV | 95 |

7.8.3 | Audible sound level | db | 55 |

7.9 | Short-circuit capability |

|

|

7.9.1 | withstand capability per unit of base current (symmetrical) |

| 35 |

7.9.2 | Duration in cycles |

| 60 |

8 | Impedance | % | 3 |

8.0.1 | Impedance tolerance |

| ±7.5% |

8.1 | Tank |

| Mild steel |

8.1.1 | Colors |

| Munsell Green |

8.2 | Total Dimentions |

|

|

8.2.1 | Height | mm | 985 |

8.2.2 | Depth | mm | 1220 |

8.2.3 | Width | mm | 965 |

8.3 | Weight |

|

|

8.3.1 | Oil | kg | 375 |

8.3.2 | Total | kg | 1386 |

8.4 | Accessories including: |

|

|

8.4.1 | Lifting lug |

| 4 |

8.4.3 | Parking stand bracket |

| 4 |

8.4.4 | LV bushing |

| 2 |

8.4.5 | Pressure relief valve |

| 1 |

8.4.6 | Drain Valve |

| 1 |

8.4.7 | Ground Strap cooper |

| 1 |

8.4.8 | HV bushing insert |

| 2 |

8.4.9 | Ground bar |

| 1 |

8.5.0 | Nameplate |

| 1 |

8.5.1 | ELSP fuse |

| 1 |

8.5.2 | Bayonet fuse |

| 1 |

8.5.3 | Tap changer |

| 1 |

8.5.4 | CEA ground bracket assy |

| 1 |

8.5.5 | Thermometer |

| 1 |

8.5.6 | Oil level gauge |

| 1 |

8.5.7 | Bushing well |

| 2 |

8.5.8 | LB Switch |

| 1 |

9 | Warranty: | Years | 2 |

Try for free information about the The Ultimate Guide to Liquid Filled Transformer

How much does a 225 kVA transformer cost?

For a 225 kva single phase pole mounted transformer, the cost is around USD 5 000 per unit.

Let’s know learn more about the NEW ZEALAND CUSTOMERS

How much does a 225 kVA transformer weight?

The weight please refer above specification.