The Most Comprehensive Introduction to Dry Type 3000 kva Transformer

In the past 20 years, with the development of the world economy, dry type transformers have achieved rapid development all over the world, especially in distribution transformers, the proportion of dry change is increasing. In this article we use 3000 kva transformer as an example, to introduce dry type transformers to our readers.

According to statistics, in developed countries such as Europe and the United States, , it has accounted for 40~50% of the distribution transformer. In China, it accounts for about 50%. From the perspective of output, the output of dry-type transformers has increased significantly since the second urban network transformation meeting in 1989. Since the 1990s, it has increased at a rate of about 20% every year. Production has approached 10,000 MVA (a value that has greatly exceeded the forecast of 45,000 MVA 10 years ago), while total production in 2002 reached 20,000 MVA and in 2004 it reached 32,000 MVA. Such a growth rate is unprecedented in the world.

So we can see China is becoming one of the largest countries of dry type transformer manufacturing and exporting.

Daelim is a professional transformer manufacturer in China, with 16 years of design, production and export of dry type transformer, distribution transformer, pad mounted transformer, single phase transformer, high voltage transformer. Professional technical team to provide you with efficient and high-quality solutions.

Pad-mounted Transformer

Dry-type Transformer

Oil immersed transformer

Table of Content

How much does a 3000 kVA transformer cost?

Before calculating the cost of 3000 kva dry type transformer, we needs to know what 3000 kva transformer consists of:

The main material is silicon steel, winding, foil, cast resin and profile.

Main accessories includes copper bars, low-voltage insulating cylinders, low-voltage airway stays, spacers, high-voltage insulators, temperature control, fans, trolley, nut, bushings, vacuum tap changer, silicone gasket, nameplate, , all kinds of bolt fasteners.

For 3000 kva cast resin transformer, DAELIM price is USD 30,000.00~40,000.00.

Below are some detailed introduction of the components:

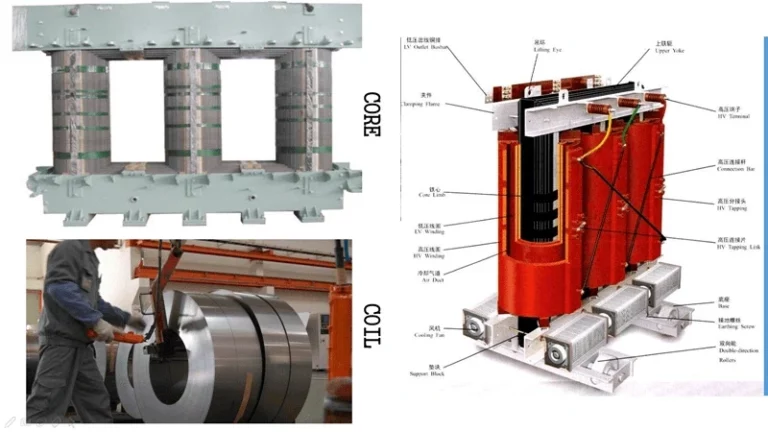

The main components of the dry-type transformer are the windings and the iron core. 1. Iron core

1) Core material . The iron core column is set with windings. In order to reduce the hysteresis loss and eddy current loss in the iron core and improve the magnetic permeability of the iron core, the iron core is made of silicon steel sheets with a silicon content of about 5%, a thickness of 0.35mm or 0.5mm, and an insulating paint or oxidation treatment on both sides. .

2) Core structure The core is divided into core structure and shell structure

(1) Core-type dry-type transformer: The primary and secondary windings of the core-type dry-type transformer are set on the two core columns of the core, as shown in the figure below. The structure is simple, and the power dry-type transformers all adopt the core structure.

(2) Shell-type dry-type transformer: The iron core of the shell-type dry-type transformer surrounds the upper and lower sides and sides of the winding, as shown in the following figure. The manufacture is complicated, and small dry-type dry-type transformers are mostly used.

2. Winding (coil): Winding has two types of material, copper and aluminium.High voltage winding: winding with high working voltage; low voltage winding: winding with low working voltage. Windings are concentric and overlapping. Overlapping winding: The high and low voltage windings are divided into a number of pie-shaped coils, which are staggered and sleeved on the core column along the height of the core column. Concentric winding 1-high voltage winding 2-low voltage winding.

Read my article on Know More About How power transformer be manufactured, tested & delivered?

How much does a 3000 kVA transformer weight?

Below we share the losses and weight of epoxy cast resin dry type 3000 kva transformer information, the winding material is copper.

| Tachnical Data for 10KV Class Three Phase Epoxy-resin Dry-type Transformer | |||||

| Rated | Connection | Short | Loss(W) | Weight | |

| Power | Symbol | Circuit | (kg) | ||

| (KVA) | Impendence(%) | ||||

| No-load | On-load | ||||

| Loss(W) | Loss(W) | ||||

| 100 | Dyn11 | 4 | 400 | 1570 | 490 |

| Yyn0 | 5 | ||||

| 160 | 540 | 2120 | 680 | ||

| 200 | 620 | 2520 | 800 | ||

| 250 | 720 | 2750 | 900 | ||

| 315 | 880 | 3460 | 1020 | ||

| 400 | 970 | 3980 | 1250 | ||

| 500 | 1160 | 4880 | 1400 | ||

| 630 | 1340 | 5870 | 1700 | ||

| 750 | 1450 | 6120 | 1800 | ||

| 800 | 1520 | 6950 | 1900 | ||

| 1000 | 1760 | 8120 | 2400 | ||

| 1250 | 2090 | 9690 | 2700 | ||

| 1600 | 2450 | 11730 | 3100 | ||

| 2000 | 3320 | 14450 | 3300 | ||

| 2500 | 4000 | 17170 | 4000 | ||

| 3000 | 4750 | 20100 | 5800 | ||

Try for free information about the power transformer specification for tender in Canada

What is the reason of dry-type 3000 kva transformer fire?

1. The insulation of the dry-type transformer is damaged and a short circuit occurs, and the insulating oil decomposes at high temperature to generate flammable gas. When it is mixed with air to a certain proportion, an explosive mixture is formed, which will burn or explode when it encounters sparks;

2. The contact resistance of the contact is too large, causing local overheating and burning the oil;

3. The casing of the dry-type transformer is damaged or flashover, the oil flows out under the pressure excitation of the oil pillow, and burns on the top cover of the bottle;

4. Due to the insulation damage between the silicon steel sheets or between the iron core and the clamping bolt, the eddy current heats up, causing the iron core to burn, which may decompose and burn the insulating oil.

Let’s know learn more about the How to purchase a 10 mva substation transformer

Under what circumstances must a dry-type 3000 kva transformer be stopped?

1. If the 3000 kva dry type transformer is burned, it must be stopped instantly.

2. By observation, if the bushing of dry type transformer is broken and discharged, we must stop the operation and consult an expert.

3. If you see smokes from the dry type transformer, it must be stopped.

4. The dry-type transformer is the carbon in the oil and the change of the oil color is too large, stop the inspection.

5. By hearing, a louder noise and may cause a explosion, must stop it to prevent any risk.

6. When the transformer is in normal operation, but the temperature indicated on controller is continuously increasing.

Keep on reading FAQ about residential transformer

What is the normal temperature for dry-type transformers?

Under normal circumstances, the thermostat control settings when the transformer is in normal operation: 80 ℃ automatic fan shutdown, 100 ℃ automatic fan start, 130 ℃ high temperature alarm, 150 ℃ ultra-high temperature trip.

First of all, it depends on what heat resistance grade your dry-type transformer is.

For the coil of the dry-type transformer, when the class A insulating material is used, when the limit working temperature is 105℃, the higher temperature rise should be less than 60K;

When using E-class insulating material, when the limit working temperature is 120℃, the higher temperature rise should be less than 75K;

When using Class B insulating material, when the limit working temperature is 130℃, the higher temperature rise should be less than 80K;

When using Class F insulating material, when the limit working temperature is 155℃, the higher temperature rise should be less than 100K;

When using H-class insulating material, when the limit working temperature is 180℃, the higher temperature rise should be less than 125K;

When the C-class insulating material is used, the higher temperature rise should be less than 150K when the limit working temperature is 220℃.

You may interested in Choose DOE Energy Efficient Single Phase Pad Mounted Transformer

What is the lifespan of a dry-type 3000 kva transformer?

Generally, the service life of dry-type 3000 kva transformers is 10-15 years, and the main reason that affects its service life is temperature. Since dry-type transformers generate high temperatures during operation, if the insulation performance of the transformer windings is poor, it is easy to cause insulation damage, resulting in the transformer not working properly, which in turn affects the service life of the transformer. If the dry-type transformer is overloaded for a long time, it will also have a great impact on its service life.

Transformer insulating materials generally withstand higher temperatures without damage, but when the temperature exceeds a certain value or when the time is too long, it will quickly age and damage.

The long-term normal operation time of the transformer under the rated voltage and rated load is related to the ambient temperature, the load condition before overload, the insulation and heat dissipation of the dry-type transformer and the heating time constant. If the dry-type transformer is overloaded and exceeds its carrying time, it will cause damage to the transformer and affect its life.

The above is an introduction to the service life of common dry-type transformers and various methods of use for your reference.

If you have any other questions about the use of dry-type transformers, please contact our manufacturers for detailed solutions!