How to produce a distribution transformer ?

What is a transformer?

Transformer (Transformer) is a device that uses the principle of electromagnetic induction to change the AC voltage.

The main components are the primary coil, the secondary coil and the iron core (magnetic core).

In electrical equipment and wireless circuits, it is often used for voltage rise and fall, impedance matching, and safety isolation.

The main functions are: voltage transformation, current transformation, impedance transformation, isolation, voltage stabilization (magnetic saturation transformer), etc.

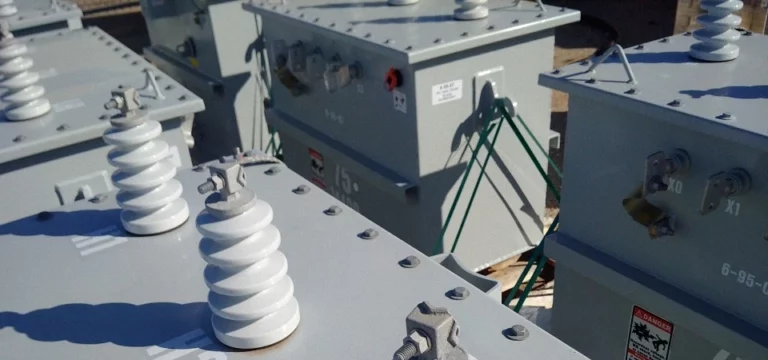

Pad-mounted Transformer

Dry-type Transformer

Oil immersed transformer

Table of Content

What are the manufacturing processes of distribution transformers?

Process Guarantee

The high-voltage coils wound by the same winding process are wound by a high-speed winding machine, which uses mechanical tension on the wire with a constant tension force. The servo system realizes the stepless gauge automatic control of the wiring, the wiring is tight and compact, and the automatic counting is accurate; due to the tension and closeness of the wire during the winding process of the high-voltage coil, the wire of the high-voltage coil is reliable and insulated from the end It is rigidly connected immediately without compression margin, and the same is true for low-voltage coils. Therefore, the axial height of the phase winding after the same winding can ensure the distribution transformer design size (thus ensuring the accuracy of the impedance voltage).

Learn more about 3 Phase Transformer Power Transformer Manufacturer Daelim

Body Assembly

Since the iron core does not have an iron yoke, the winding type phase unit, the iron yoke pad is made of injection-molded epoxy resin pads, and the insulation of the high-voltage leads and tap leads adopts special matching combinations such as reinforced PVC pipe sleeves. The distribution transformer body insulation and lead assembly are carried out on the rolling platform assembly line, the assembly speed is fast, the quality is good, and it is clean and hygienic.

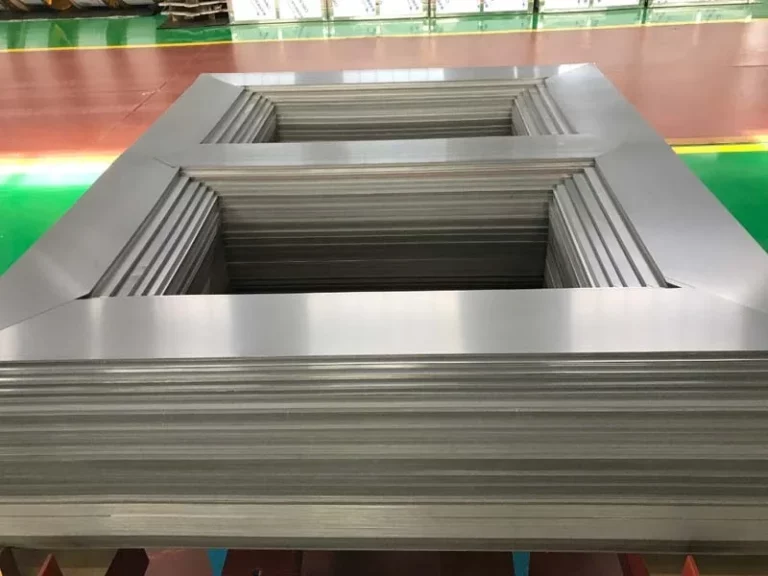

Corrugated Fuel Tank

The corrugated fuel tank uses the “corrugated sheet folding machine” in the corrugated production line to automatically fold cold-rolled steel sheet coils into the sheet shape required by the design drawings, including the corrugated height, pitch, corrugated sheet, straight edge length and Total length and width.

The folding quality is good and the speed is fast; the corrugated sheet is folded and then enters the welding to complete the folded end seam and the reinforced iron welding. This welding adopts argon arc welding, the welding arc is stable, the welding seam penetration is large, and the shape is good without defects. The corrugated fuel tank has a bottom, a side, and a rectangular mailbox formed by butt welding of corrugated sheets in the middle. The corrugated sheet is folded and processed by thin plates. In addition to good heat dissipation performance when the distribution transformer is working, the corrugated sheet’s corrugated fin also has the function of expansion to relieve the internal pressure rise.

Daelim has completed the manufacture of 85 sets of 200kva distribution transformers in May and June. This type of distribution transformer is using a circuit breaker protection system to the traditional distribution transformer and is called a completely self protective transformer(CSP). They will be shipped to Kenya to provide power transmission to the local power company Kengen, bringing stable electricity to more local people.