All Things You Need to Know About 75 kva Transformer

Daelim 75 kva transformer includes single phase and three phase type. Oil type and dry type.

Oil insulated distribution transformer (what is distribution transformer?), we have single phase pole mounted type, single phase pad mounted type, three phase pad mounted type. Also there are isolation transformers,case resin transformers.

This article is mainly talks about things about 75 kva single oil filled single phase pole mounted transformer and pad mounted transformer.

Pad-mounted Transformer

Dry-type Transformer

Oil immersed transformer

Click below for quick review of 3 phase transformer

How to calculate kw and kva?

KVA is the unit of capacity, and KW is the unit of load power.

Generally, the transformer capacity is selected considering the power factor, that is, if the rated total power of the electrical equipment is 60KW, considering that the power factor is calculated as 0.8, a transformer of 60/0.8=75KVA should be selected.

Try for free information about the WHAT ARE THE STANDARD ACCESSORIES FOR PAD MOUNTED TRANSFORMER

What is a 75 kva single phase pole mounted transformer?

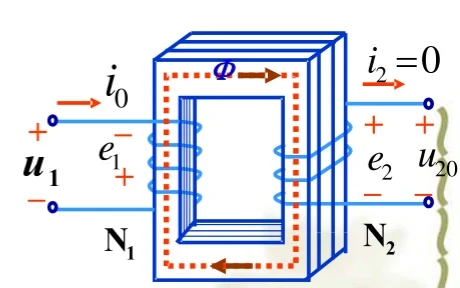

Below is a drawing show how transformer works, it uses principle of electromagnetic induction, transform voltage U1 to U2. Iron core and winding are the medium that realizes this principle.

Let’s know learn more about the AUSTRALIA CUSTOMER

The main functions of single phase pole mounted transformer:

change voltage, change current, change the impedance, etc.

Keep on reading Basic Guide to Different Transformer Types

The application of single phase pole mounted transformer:

power transmission and distribution, and are widely used in industry, agriculture, transportation, urban communities and other fields.

Transformer body(iron core – silicon steel sheet, conductor-aluminium or copper, insulation paper, lead wire), oil, enclosure, tap changer, and protection equipment (Silicone moisture absorber, oil level indicator, oil temperature indicator, gas relay, oil conservator) and high and low voltage bushings.

Iron core

Main components and usage:

Daelim’s transformer cores uses cold-rolled silicon steel sheets, compare with previous hot-rolled silicon steel sheets, it’s weight and size are smaller. Cold-rolled silicon steel sheets maintain higher magnetic permeability when magnetized along the rolling direction. The 0.35mm thick grain-oriented cold-rolled silicon steel sheet improves the structure of the core and reduces the no-load loss.

Winding

The winding is the circuit part of the transformer, and the winding material is insulated flat wire or enameled round wire. The primary winding of the transformer is a resistor connected to the power supply and can receive energy from the power supply; the secondary winding is connected to the load and provides energy to the load.

The winding material used by Dalin has excellent resistance to transformer oil, scratch resistance, strong flexibility and good electrical performance.

Single-phase transformer: that is, a transformer in which both the primary and secondary windings are single-phase windings.

You may interested in Basic Guide To GSU Transformer

The significance of adopting this structure is as follows

First, use less material. The single-phase transformer of the same capacity uses 20% less iron and 10% less copper than the three-phase transformer. Especially when the wound iron core structure is adopted, the no-load loss of the transformer can be reduced by more than 15%, and the best life cycle cost can be obtained.

The second is to save cable costs. Using a single-phase power supply system can cut wires by more than half. In terms of current density, it can save about 40% of the weight of the wire. From the perspective of mechanical strength, the consumption of pickles is reduced by about 60%

The third is to improve production efficiency. The single-phase transformer is relatively simple in design, can be produced quantitatively, and has a shorter delivery time than other transformers.

75 kva single phase pole mounted transformer specification

The winding temperature wise of a 75kva single phase transfomer is 65℃,the insulating liquid not exceed 65℃, and 80℃ is the hottest-spot temperature rise.

The minimium impedance of 75kva single phase pole mounted transformer, low voltage rating below 600V is 1.5%

Know more about CANADA CUSTOMERS

75kva single phase pole mounted transformer installation

1. The transformer should be set up near the load center or large users. It is necessary not only to consider the convenience of maintenance, but also to avoid places with many vehicles and pedestrians.

2. It is strictly forbidden for low-voltage wires to pass through high-voltage down-conductors.

3. After the transformer is installed, the bushing should be smooth and clean, and there should be no cracks, breakage, etc. The bushing crimping bolts and other parts should be complete, and the installation should be firm; the oil level is normal, and the casing is clean

Try for free CONGO CUSTOMER

75 kva single phase pole mounted transformer standard features

Taps will be provided if specified, the general tapping range is ±2*2.5%, ,option is none above, 4 2.5% below.

Single phase pole mounted transformers are with Lifting lugs, Low voltage terminals, HV bushings, oil fill plug, grounding pads.

The high voltage can be 4800/8320Y, 7200/12470Y, 7620/13200Y, 13200/22860Y, 13800/23900Y, 14400/24940Y, 12000, 13200, 13800, 16430, 34500V, low voltage can be 120/240, 240/480, 346 or 600, 2400 or 4800, 7200 or 7620 or 797V.

What is a 75 kva three phase pad mounted transformer?

The pad mounted transformer in the United States is divided into two types: with operation corridor (staff operate inside the box) and without operation corridor (staff operate outside the box).

The 75 kva pad mounted transformer can be an integral box or a split box composed of two, three or more boxes.

The box should have sufficient mechanical strength and should not be deformed during transportation and installation. Should strive for beautiful appearance, color and environmental coordination.

The high and low voltage rooms of the enclosure should be equipped with lighting lamps, and dustproof and anti-condensation measures should be taken. The humidity of the high and low voltage rooms should not exceed 90% (25°C), and the transformer room should be well ventilated. The box shell should have measures or devices such as sun protection, rain protection, rust prevention, and entry of small animals.

After the 75 kva pad mounted transformer installed, how to carry out the leak test?

Pad mounted transformer can bear 2 times overload for 2 hours and 1.6 times of overload for 7 hours without affecting the life of the transformer.

The After the transformer is installed, the leak test should be carried out on the oil conservator with air pressure or oil pressure. The pressure is that the oil tank cover can withstand 0.03Mpa pressure. The test duration is 24h, and there should be no leakage. For transformers transported as a whole, no sealing test is required.

Pad mounted transformer application

The 75 kva pad mounted transformer is to put the transformer body, LBS, bayonet fuses, tap changer, valves and other indicators together.

Small size, compact structure, tamper-proof design, easy installation, and low maintenance requirements. Pad mounted transformer is generally installed on a low masonry or concrete platform 20~30CM above the ground. There should be safety signs such as high voltage danger on the transformer. The door should be locked and kept by a special person to prevent electric shock accidents caused by people and animals approaching the live parts.ons, schools and other places

Read my article on How to Choose a Pad Mounted Transformer and Delta Wye Transformer?

Maintain of 75 kva pad mounted transformer

After the installation and use of the pad mounted transformer, there is basically no need for maintenance. However, because of some reasons, it also requires maintenance in some cases :

The anti-rust treatment of the shell does not meet the specifications, and more confirm whether it is rusted;

In some projects, the pad mounted transformer will be filled with inert gas. For some required projects, moisture and moisture enter the oil, the electrical insulation performance will be significantly reduced, and it is easy to break down. The long-term contact of transformer oil with oxygen in the air will produce acid, resin, and sediment, which will seriously deteriorate the insulating material.

Since the pad-mounted transformer is used outdoors, it should be checked frequently, because the casing leaks oil due to accidental collision with the oil tank.

In addition, the fuse of the box change should be checked regularly to see if it is in good condition

Try for free information about the How to produce a distribution transformer ?

What is the loss level of 75 kva transformer?

As per DOE 2016, for single phase pole mounted 75 kva , the efficiency is 98.5%.

For three phase pad mounted 75 kva, the efficiency is 99.03%.

The transformer should be as per IEEE Std C57.12.20.

Let’s know learn more about the EAF TRANSFORMER MEXICO

What is the weight of a 75 kVA transformer?&How to deliver 75 kva transformer?

Below is the dimension for single phase pole mounted transformer

Rated Power (KVA) | Dimension(mm) | Weight(KG) | |||

| W | D | H | Oil Weight | Total Weight |

5 | 465 | 485 | 855 | 15 | 92 |

10 | 500 | 525 | 885 | 22 | 150 |

15 | 520 | 565 | 905 | 30 | 210 |

25 | 560 | 590 | 935 | 45 | 258 |

37.5 | 610 | 625 | 935 | 50 | 340 |

50 | 635 | 675 | 1035 | 62 | 395 |

75 | 745 | 840 | 1035 | 88 | 480 |

100 | 770 | 965 | 1135 | 94 | 530 |

167 | 795 | 890 | 1335 | 138 | 680 |

For 75 kva, generally it is 26 units in one 40 foot container.

Below is the dimension for three phase pad mounted transformer

Rated Power (KVA) 额定容量 | High Voltage (V) 高压 | Low Voltage (V) 低压 | Dimension(mm) 尺寸 | Weight(KG) 重量 | |||

|

|

|

|

| |||

|

|

|

|

| |||

|

|

|

|

| |||

|

|

| W 宽 | D 深 | H 高 | Oil Weight 油重 | Total Weight 总重 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

75 | 34500/ 19920 13800/ 7957 13200/ 7620 12470/ 7200 or others | 240 480 480Y/ 277 600Y/ 347 | 1390 | 910 | 1430 | 120 | 645 |

112.5 |

|

| 1420 | 920 | 1430 | 138 | 729 |

150 |

|

| 1510 | 980 | 1530 | 201 | 989 |

225 |

|

| 1600 | 1000 | 1660 | 230 | 1195 |

300 |

|

| 1660 | 1080 | 1680 | 260 | 1415 |

500 |

|

| 1810 | 1160 | 1790 | 325 | 1905 |

750 |

|

| 2030 | 1300 | 2030 | 535 | 2755 |

1000 |

|

| 1651 | 1549 | 1854 | 650 | 3235 |

1500 |

|

| 2210 | 1470 | 2150 | 748 | 5835 |

2000 |

|

| 2380 | 1600 | 2220 | 950 | 6430 |

2500 |

|

| 3070 | 1650 | 2330 | 1020 | 8865 |

For 75kva, generally it is 10 units in one 40 foot container.

Keep on reading Electrical transformer – DAELIM BELEFIC

How to make 75 kva transformer?

1). Manufacture of fuel tanks and accessories.

1. Blanking (cutting, gas cutting, machining blanking).

2. Fuel tank and accessories pair,

Welding and adjustment.

Derusting, slag removal and cleaning of fuel tank and accessories.

Fuel tank and Pickling and leak testing of accessories (mechanical strength test of fuel tank).

5. Fuel tank and accessories spray paint.

Learn more: How to Choose a Pad Mounted Transformer and Delta Wye Transformer

2) the manufacture of coils.

1. The first is the production and preparation of insulating parts

2. Coil winding, standing up, shaping, a series of treatments such as drying, pressing, dipping and drying are carried out to prepare the body for assembly.

3) Transformer assembly.

1. Iron core manufacturing, including cutting of silicon steel sheets, pre-stacking of silicon steel sheets, iron core assembly, iron core binding and furnace drying, iron core test.

2. Body assembly, including insulator assembly and coil lead wrapping treatment, wire ring set, insert board and clamp iron, semi-finished product test for body, lead assembly (including. switch assembly, manufacture and assembly of lead wires), semi-finished product testing of the body, and insertion of the body 0ven drying (including insulation resistance measurement).

3. General assembly, including the finishing and tightening of the body, the insulation resistance of the iron core to the ground measurement, check the cleanliness of the body and the tightness of each component, the wiring and lead

Line insulation distance, packing oil (including the installation of transformer accessories), submitting for inspection, making changes

After the test is passed, the compressor is disassembled and packaged, and the warehousing procedures are handled.

You may interested in Introduction of a special transformer – furnace transformer

What is the nameplate of 75 kva transformer?

According to IEEE C57.12.00 Std, the nameplate of 75 kva transformer shall include below contents:

Serial number

Date of manufacturer

ONAN

Single or three phases

60Hz

75 kva

Voltage rating

Temperature rise

Polarity

Phasor diagram

Impedance

Approximate total mass in kg or lb

Connection diagram

Daelim factory address and name

Installation and operating instruction reference

Mineral oil or FR3 oil

Aluminium winding or copper winding

Liquid level

DOE 2016 complaint