The Ultimate Guide to Liquid Filled Transformer

What we are talking about when it comes to liquid filled transformer

Liquid filled transformer is also called oil-immersed transformer, it is a commonly used transformer product, and it is one of the important equipment in the electrical system of I mining enterprises and civil buildings.

There are many types of liquid immersed transformer, today let’s going to learn more about it.

Pad-mounted Transformer

Dry-type Transformer

Oil immersed transformer

Table of Content

What is a liquid transformer?

Oil-filled transformers, as the name suggests, are filled with liquid inside the transformer.

It is the opposite of a dry transformer, also called a wet transformer. 80% of the grid uses oil-filled transformers.

What liquid is in a transformer?

It can be mineral and vegetable oil.

What is the limit of the winding temperature rise of the liquid filled transformer?

Under the specified cooling conditions, the oil-immersed transformer can operate according to the regulations on the nameplate, but the top oil temperature should not exceed 90°C,80°C.

Between the silicon steel sheets of the oil-immersed transformer, due to the long-term immersion in the transformer, the oil can penetrate into it, and the transformer oil has an elastic buffering effect, so the noise of the oil-immersed transformer is small.

Read my article on Know More About Tips of single phase transformer

Is the noise level of pad mounted liquid filled transformer loud?

There are many cases of noise in pad mounted liquid filled transformers.

For common ground-type pad mounted transformers, the noise will affect the operation of pad mounted transformers, which is also unfavorable for the operation of pad mounted transformers.

The noise of common ground-type pad mounted transformers should be How to control it? After the noise of the pad mounted transformer occurs, it must be dealt with, so that the smooth operation of the pad mounted transformer can be ensured. The noise of the pad mounted transformer should be handled in this way? The reasons for the noise are as follows For several reasons:

The noise of the pad mounted transformer is mainly caused by the internal structure and electromagnetic properties of the pad mounted transformer.

Since most of them are low-frequency noise and slight vibration, if the pad mounted transformer is relatively close to the human body, it will cause a sense of inapplicability, which can seriously cause the human body. Due to various physical and mental diseases such as weakened immunity, the noise problem cannot be ignored.

The more common treatments are:

1. A reasonable magnet density is adopted in the treatment of pad mounted transformers

2. The iron core will be fixed and clamped

3. Take foot vibration damping measures under the whole pad mounted transformer

4. It is better that internal professionals can maintain all-round maintenance. After a long time, there may be looseness. The fixed fixed

5. The fan adopts low noise

6. The installed platform can be stable and reliable

7. It is also possible to install sound insulation cover or sound insulation measures for the overall computer room

8. Special personnel are required for regular maintenance

Of course there are other measures, such as:

1. In addition to controlling the winding tension when winding, the tension of the insulating tape should also be controlled;

2. Dip insulating oil (paint) and fasten the iron core and rubber core with glue, and fix the two iron cores can also help reduce noise.

Try for free information about the VENEZUELA CUSTOMERS

What is the most common liquid used in transformers?

Transformer oil is a liquid medium with good insulating properties, and it is mineral oil. Transformer oil is a kind of mineral oil obtained by distillation and refining of natural petroleum. It is the lubricating oil fraction in petroleum that is purified and stable, with low viscosity, good insulation and good cooling performance.

Mixture of liquid natural hydrocarbons.

Commonly known as square shed oil, light yellow transparent liquid.

Mineral oil refers to a mixture of refined liquid hydrocarbons obtained from petroleum, mainly a mixture of saturated naphthenes and paraffins, obtained from crude oil by atmospheric and vacuum fractionation, solvent extraction, and dewaxing and hydrorefining. Mineral oils include light and heavy fuel oils, lubricating oils, cooling oils and other mineral hydrocarbons. Mineral oil can float on the surface of the water body, affecting the oxygen exchange between the air and the water body;

it can also be dispersed in water, adsorbed on suspended particles or in the water in an emulsified state.

Keep on reading VIETNAM CUSTOMERS

What is the difference between liquid filled transformer and dry transformer?

2. Different lead forms

Different dry-type transformers mostly use silicone rubber bushings, while most oil-type transformers use porcelain bushings.

3. Different capacity and voltage

Dry-type transformers are generally suitable for power distribution. Most of them have a capacity below 1600KVA and a voltage of 10K. Some of them have a voltage level of 35KV, while oil-type transformers can achieve full capacity from small to large, and all voltage levels have been achieved. Voltage, the UHV 1000KV test line under construction in my country must be an oil-type transformer.

4. Insulation and heat dissipation are different

Dry-type transformers are generally insulated with resin, relying on natural air cooling, and large-capacity cooling by fans, while oil-type transformers rely on insulating oil for insulation, and the circulation of insulating oil inside the transformer transfers the heat generated by the coil to the radiator of the transformer for heat dissipation. .

5. Applicable places

Dry-type transformers are mostly used in places that require “fireproof and explosion-proof”, and are generally easy to use in large buildings and high-rise buildings, while oil-type transformers may spray or leak oil after an “accident”, causing fires, and most of them are used outdoors, and There are places where “accident oil pools” are dug.

6. Different load bearing capacity

Generally, dry-type transformers should operate at rated capacity, while oil-type transformers have better overload capacity.

7. The cost is different

For transformers of the same capacity, the purchase price of dry-type transformers is much higher than that of oil-type transformers. Dry-type transformer models generally start with SC, epoxy resin casting encapsulation type, SCR non-epoxy resin casting solid insulation encapsulation type, and SG open type. Different dry-type transformers mostly use silicone rubber bushings, while most oil-type transformers use Porcelain casing.

Learn more about 3 Phase Transformer Power Transformer Manufacturer Daelim

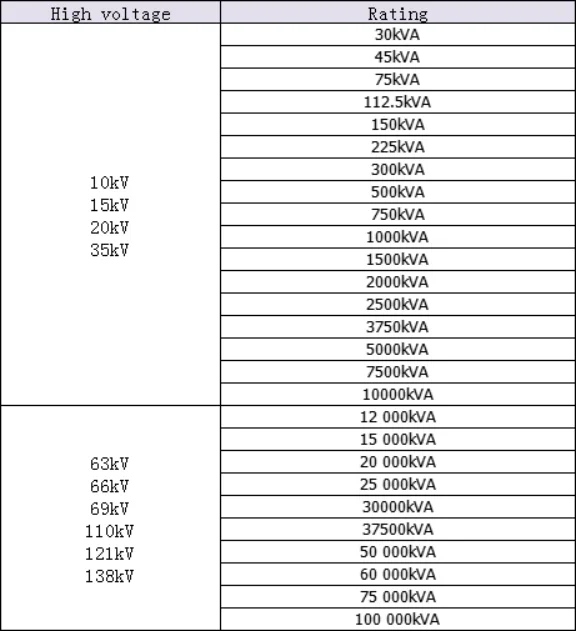

What is liquid filled transformer ratings?

According to IEEE standard, ratings are as below:

Keep on reading Come to know more about DAELIM 15 mva transformer

How long is the liquid filled transformer life expectancy?

The long-term normal operation time of the transformer under the rated voltage and rated load is called the service life of the transformer. There are two categories of materials for making transformers: metal materials and insulating materials. Metal materials can generally withstand higher temperatures without damage, but insulating materials will quickly age and damage when the temperature exceeds a certain value, so temperature is one of the main factors affecting the service life of transformers. The life of the transformer can be said to be the life of the insulating material in a certain sense.

The phenomenon that insulating materials gradually lose their original mechanical properties and insulating properties under the action of electric field and high temperature for a long time is called aging. The rate of aging mainly depends on the following factors:

(1) The temperature at which the insulation is located.

(2) Moisture content of insulating materials.

(3) For oil-immersed transformers, the oxygen dissolved in the oil should also be considered.

The above three factors determine the service life of the transformer. Practice and research have shown that if the winding can maintain a temperature of 95 ℃ continuously, the service life of the transformer can be guaranteed for 20 years. According to the relationship between temperature and life, a so-called 8°C rule can also be derived: based on the life at the above temperature, the service life of the transformer is shortened by 1/2 for every 8°C increase in the winding temperature.

You may interested in 15kva transformer Tips

Customized Liquid Transformers

Daelim belefic is China’s top transformer brand, focusing on overseas markets for nearly 20 years. The team has rich experience in international standard transformer design and export. Daelim’s technical team can customize the liquid filled transformer according to your technical requirements and parameters. If you have any technical questions and problems about liquid filled transformers, you can ask Daelim team to help you solve them.